6 Coordinate Systems

Allows up to 6 jobs to be run consecutively in a single set up

3 Step Control of EDM Parameters

Program up to three EDM parameter settings per hole to improve hole quality on difficult entrance and exits

Automatic Electrode Changer

Allows for a large volume of unattended operation

Automatic Electrode Stabilizer

Moves automatically to provide extra support for long electrodes

1000 RPM Programmable Spindle

Rotation speed is adjustable and will reduce cycle time for some applications

Windows Based

With conversational G and M Code programming

Multi-Tasking Abilities

Create and edit one program while the machine is running another

Ethernet Connectivity and USB Support

For programming and transferring of data

Automatic Depth Control

Generate blind holes reliably without operator intervention

Linear Glass Scales with 1 Micron Resolution

Provides true, closed loop, position feedback for precise part positioning accuracy

Auxiliary I/O

Ability to interface with ancillary devices such as rotary tables, indexers, and work piece handling systems

Integrated Rotary and Tilt/Rotary Tables (optional)

Programmable tilt and rotary systems for complex parts requiring multi axis positioning

Break Through Detection (optional)

Ensures a complete hole or helps to eliminate back wall strikes

Optical Inspection System (optional)

High resolution video camera can measure hole size, verify position, and locate datum points for part programs

EDM Power Booster (optional)

Increases the maximum average current which will reduce the cycle time when using larger diameter electrodes

EDM Milling (optional)

EDM mill shaped diffuser holes using standard cylindrical electrodes

6 Point Probing (optional)

Probe the work piece to determine its 5 axis location and offset position in the part program

Coaxial Flush (optional)

A special guide and guide sleeve delivers auxiliary flush down the guide body

Programmable High Pressure Flush (optional)

Adjust the high pressure flush pressure through the electrode with a G-Code in the part program

| TRAVEL | |

| X Axis | 39.3″ (1,000 mm) |

| Y Axis | 47.2″ (1,200 mm) |

| W Axis | 39.3″ (1,000 mm) |

| Z Axis | 15.7″ (400 mm) 23.6″ (600 mm)** |

| Open Height | |

| Minimum | 3.1″ (80mm) |

| Maximum | 39.3″ (1,000 mm) |

| WORK TABLE | |

| Width x Depth | 43.3″ x 51.1″ (1,100 x 1,300 mm) |

| WORK PAN | |

| Width x Depth | 59.0″ x 70.8″ (1,500 x 1,800 mm) |

| WEIGHT CAPACITY | |

| On Work Table | 5,500 lb. (2,500 kg.) |

| GENERATOR | |

| Maximum Average Current | 30A, 60A** |

| On and Off Time | 1 to 99 μs |

| Capacitors | 0 to 1.81 μF |

| AUTOMATIC ELECTRODE AND GUIDE CHANGER | |

| AEC Positions | – |

| AGC Positions | – |

| FLOOR SPACE AND WEIGHT | |

| Width x Depth x Height | 104″ x 134″ x 138″ (265 cm x 341 cm x 350 cm) |

| Machine Tool Weight | 12,100 lb. (5,500 kg.) |

| ENVIRONMENTAL | |

| Room Temperature | 68 to 77°F (20 to 25°C) |

| Relative Humidity | 40% to 55% |

| UTILITIES | |

| Electrical | 220VAC ±10%, 3 PHASE, 60 Hz, 3.5 KVA |

| Air | 90 PSI@ 1 CFM (6 BAR@ 1.7 CMH) |

| TRAVEL | |

| X Axis | 39.3″ (1,000 mm) |

| Y Axis | 47.2″ (1,200 mm) |

| W Axis | 39.3″ (1,000 mm) |

| Z Axis | 15.7″ (400 mm) 23.6″ (600 mm)** |

| Open Height | |

| Minimum | 3.1″ (80mm) |

| Maximum | 39.3″ (1,000 mm) |

| WORK TABLE | |

| Width x Depth | 43.3″ x 51.1″ (1,100 x 1,300 mm) |

| WORK PAN | |

| Width x Depth | 59.0″ x 70.8″ (1,500 x 1,800 mm) |

| WEIGHT CAPACITY | |

| On Work Table | 5,500 lb. (2,500 kg.) |

| GENERATOR | |

| Maximum Average Current | 30A, 60A** |

| On and Off Time | 1 to 99 μs |

| Capacitors | 0 to 1.81 μF |

| AUTOMATIC ELECTRODE AND GUIDE CHANGER | |

| AEC Positions | 20, 30** |

| AGC Positions | 12** |

| FLOOR SPACE AND WEIGHT | |

| Width x Depth x Height | 104″ x 134″ x 138″ (265 cm x 341 cm x 350 cm) |

| Machine Tool Weight | 12,540 lb. (5,700 kg.) |

| ENVIRONMENTAL | |

| Room Temperature | 68 to 77°F (20 to 25°C) |

| Relative Humidity | 40% to 55% |

| UTILITIES | |

| Electrical | 220VAC ±10%, 3 PHASE, 60 Hz, 3.5 KVA |

| Air | 90 PSI@ 1 CFM (6 BAR@ 1.a7 CMH) |

Belmont SY-1210 at IMTS 2024

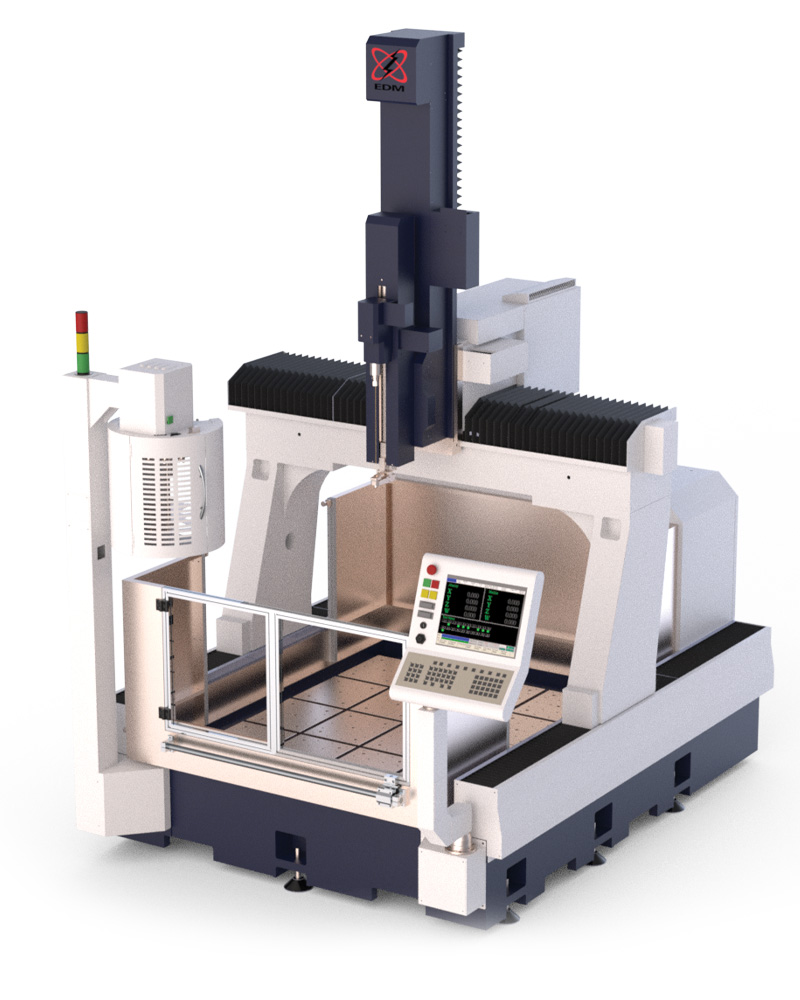

SY-1210T30GUR CNC Drill

Programmable Flush Pressure